Home > Applications > Bridge Monitoring > Overweight Monitoring

Monitoring overweight loads on bridges is crucial for maintaining structural health of bridges and preventing damage. Overweight vehicles can cause significant strain, leading to potential failures and long-term deterioration. Resensys offers wireless monitoring system designed to detect and document instances of load-rating violations, providing both strain measurements and visual evidence.

•

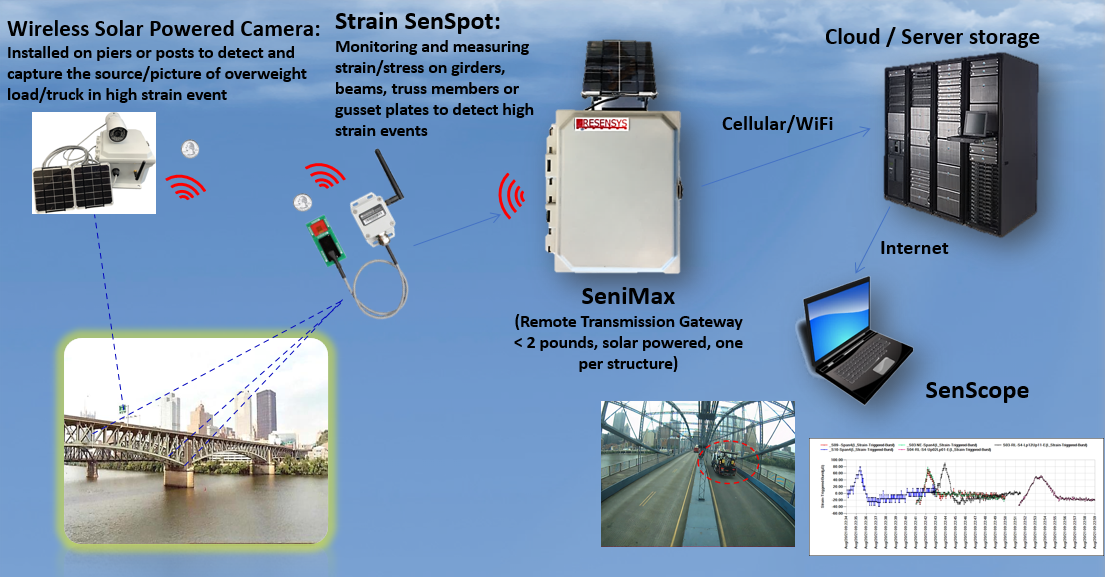

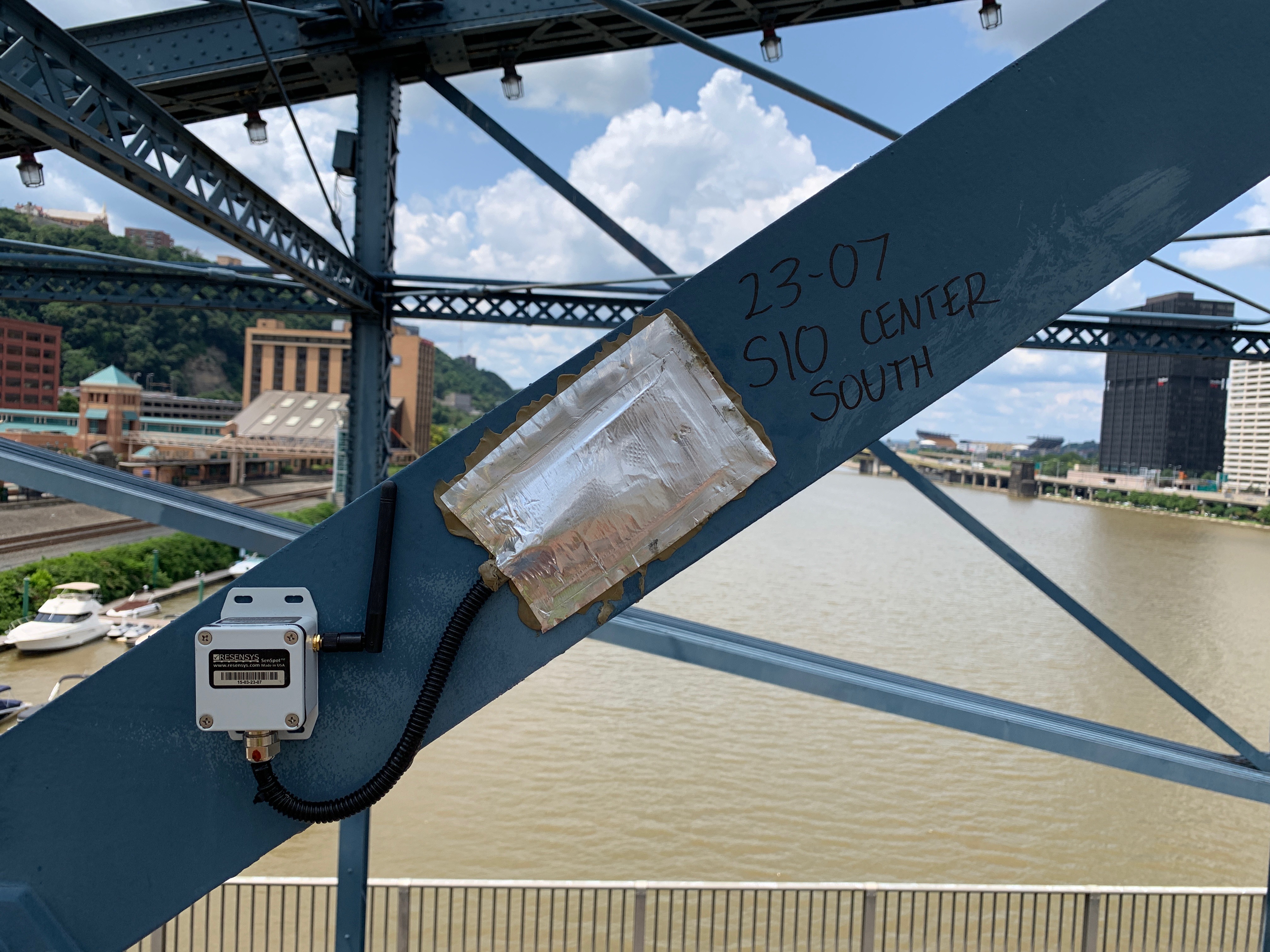

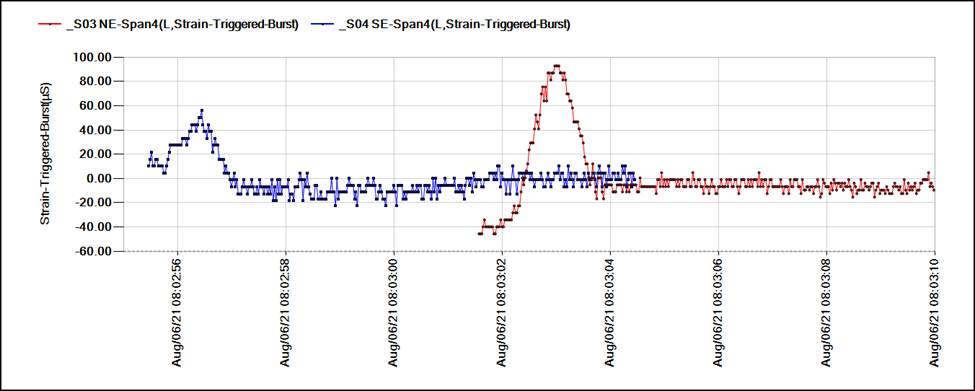

Wireless Strain Gauge SenSpot™: These SenSpot™ sensors continuously monitors strain in load-bearing members of the bridge. After establishing baseline strain readings with controlled test trucks, the system uses these values as thresholds to detect potential overweight loads.•

Wireless Solar-Powered Camera: The Wireless Solar-Powered Camera is activated upon detection of strain levels that exceed the pre-set threshold. The camera captures images of the vehicle responsible for the overweight load, providing visual evidence without requiring an external power source. The camera remains powered off until triggered, making it highly efficient and sustainable.

• Wireless and Efficient: The wireless design of both the strain gauge and the camera eliminates the need for extensive wiring, reducing installation costs and time. The minimal lane closure requirement ensures minimal disruption during installation.• Long-Term Monitoring: With a battery life exceeding 10 years, these sensors offer reliable, long-term monitoring without frequent maintenance.• Adaptability: Suitable for various materials including steel, concrete, timber, and composites, and capable of operating in extreme weather conditions, the system is versatile and robust.• High Precision: The Wireless Strain Gauge SenSpot™ offers a resolution of 1 microstrain and a sampling rate of 20-100 samples per second, ensuring accurate and timely data collection.• Data Visualization and Analysis: The system includes SenScope™ software for comprehensive data analysis, visualization, and automated alert management. This software also integrates with the camera system to provide visual documentation of load violations.

This system reduces installation cost and time for authorities to get the accurate data and detailed visual feedback they need to manage and mitigate the risks associated with overweight loads, ultimately enhancing bridge safety and longevity. A unique feature of Resensys wireless strain gauge SenSpot™ sensors is their ability to measure at a high sampling rate and resolution while maintaining ultra-low power consumption.

A Resensys monitoring system for overweight load detection typically includes the following components:

Wireless Strain Gauges SenSpot™ Sensors:These are strategically placed on critical elements of the bridge, as determined by inspections and modeling. The number of gauges required per structure is usually dependent upon the design, existing issues on members and project needs.SeniMax™ Gateway: This wireless data logger collects sensor data and transmits it to a cloud database. One SeniMax™ can support up to 120 sensors within its range.

Wireless Solar Powered Cameras:Positioned on piers or light posts to capture images of overweight vehicles during high-strain events. Required number of cameras are determined according to project requirements. SenScope™ Software:Used for data analysis, visualization, and integration of sensor data with captured images.

Resensys' wireless monitoring system delivers a powerful and reliable solution for safeguarding bridges from the structural damage caused by overweight vehicles.

For more information on how Resensys can help you effectively monitor overweight vehicles on bridges and ensure structural safety, Contact Us today to discuss your specific needs.

Figure below shows a picture of a practical Resensys SHM system, which can be used for monitoring instances of overweight loads on bridges.