Home > Application Notes > Bridge Load Rating

Accurate and up-to-date inventory and operating ratings are essential for meeting inspection and reporting requirements, ensuring proper bridge postings, and enabling informed asset management decisions. These ratings help infrastructure owners manage traffic patterns, plan for asset rehabilitation or reinforcement, and ensure the safe operation of bridges under current or changing demands.

DOTs, authorities, and other asset owners invest significant resources in validating and refining load rating models. They also work to ensure compliance with rule changes that may require re-rating bridges based on updated truck requirements.

Resensys offers a reliable and breakthrough wireless solution for bridge load rating, providing precise strain measurements with a host of cost-effective benefits:

•

Wireless Strain Gauges: No wiring required, minimizing lane closures during installation.• 10+ Years Battery Life: Long-lasting sensors do not need for battery replacement, maintenance, or calibration in the field.• Easy Installation: Sensors can be quickly and easily attached using adhesive mounts (for steel) or flange mounts (for concrete).• Quick Testing: Ideal for short-term load rating tests, easy to remove and reuse on other structures.• Long-term Monitoring: Designed for extended use, providing accurate data over several years.• Compact and Lightweight: Small sensors that can be used on various materials, including steel, concrete, timber, and composites.• Rugged, Weatherproof, and Corrosion Resistant: Built to operate in harsh conditions, including extreme weather, high humidity, and salty environments (-40°C to +65°C or -40°F to +150°F).• Infrastructure-Less: Battery-operated and energy self-sufficient, requiring no communication infrastructure at the bridge site.• High Precision: Wireless Strain Gauge SenSpot™ sensors offer very high precision (1 microstrain) with high sampling rates.

This system reduces installation cost and time for owners/authorities to get the accurate data they need for load rating. A unique capability of Resensys Wireless Strain Gauge SenSpot™ sensor is to measure at high sampling rate and resolution, while providing ultra-low power usage.

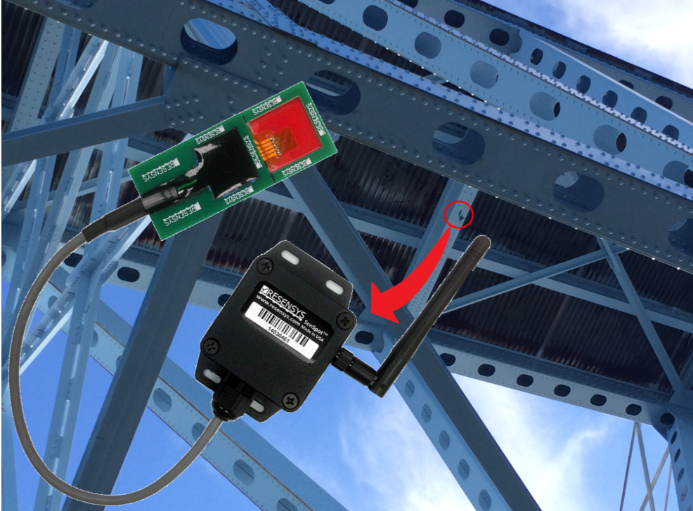

1. Attach Sensors: Adhesive mount wireless strain SenSpots™ to critical structural members such as beams, girders, truss members, and gussets.

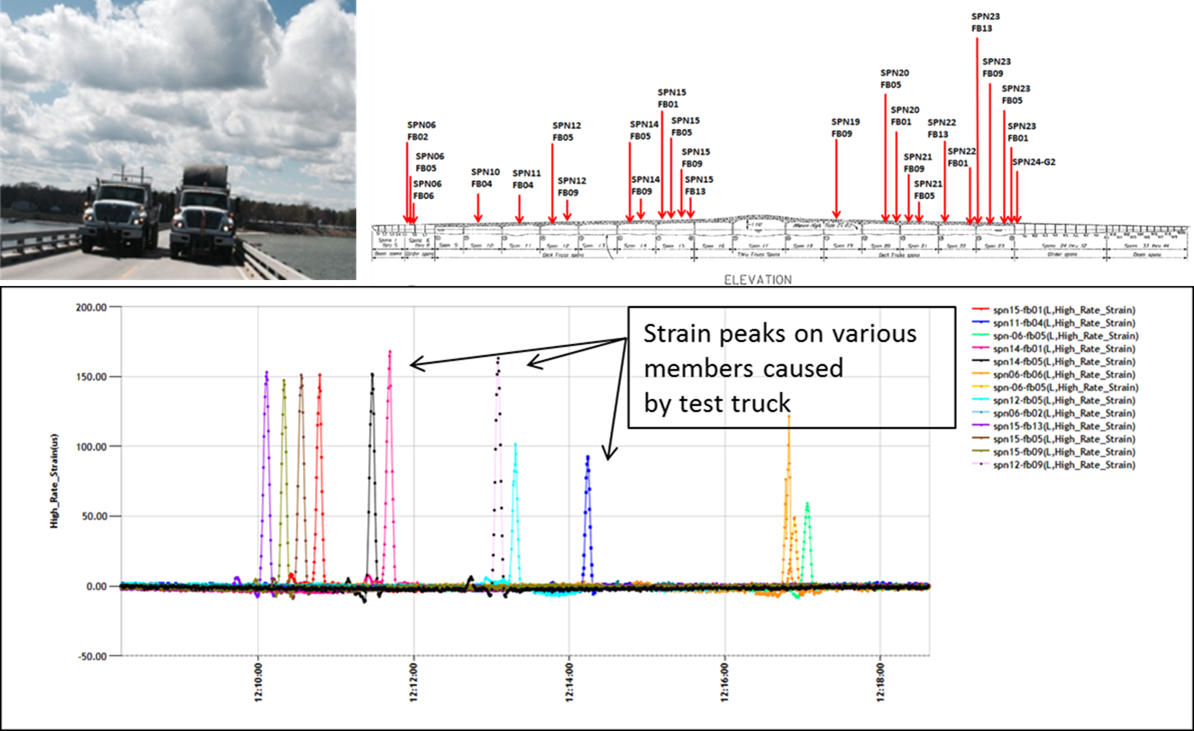

2. Conduct Load Test: Drive a truck with a known weight (steer axle, drive tandem axle, and gross weight) over the bridge.

3. Calculate Load Capacity: Use the collected data to calculate the load-carrying capacity based on the structural response.

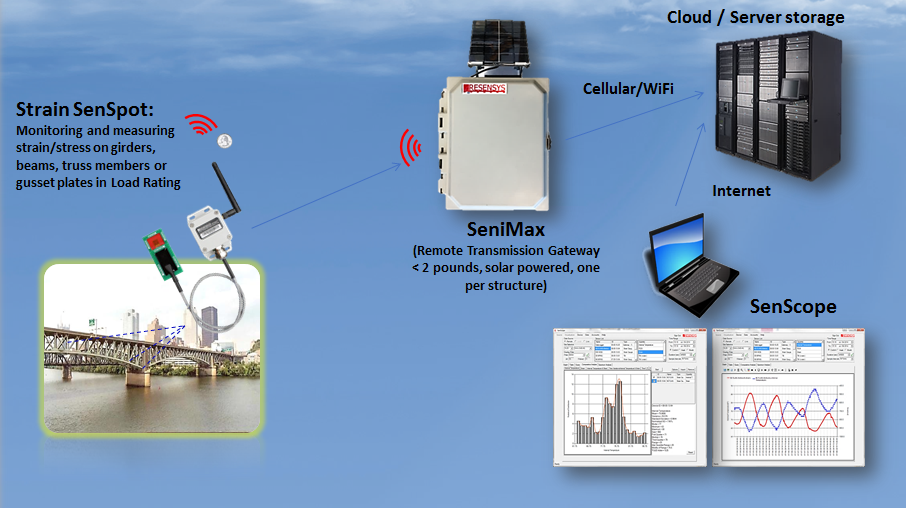

Resensys system for Bridge Load Rating includes the following components:

•Wireless Strain Gauge SenSpot™: Attached to critical structural elements based on inspection, modeling, or client recommendations. The number of gauges required per structure is usually dependent upon the design, existing issues on members and load rating needs.

• SeniMax™: A wireless data logger that collects sensor data on-site and transmits it to a cloud database via cellular or satellite networks.

• SenScope™: Used for data analysis, visualization, export, automated alerts, thermal analysis, and generating load rating graphs.

This advanced system reduces installation costs and time, providing authorities with the accurate data needed for effective load rating.

Contact Us to learn how Resensys can help to accurately assess and manage bridge load ratings.

The figure below shows a practical Resensys Structural Health Monitoring (SHM) system, which can be used for Bridge Load Rating.

More Details

More Details