Home > Applications > Bridge Monitoring > Routine/ Contract Bridge Load Rating Validation

Load Rating is the safe live load that carries capacity of a highway bridge structure. Rating Factor (RF) is defined for concept of load rating and in terms of tonnage for a particular vehicle. Load rating is significant because different kind of vehicles have been used in the past for the design of bridges (e.g., H-15, HS20-44, HL-93, etc.) and some bridges are old, depreciated or become structurally deficient during their lifetime. All bridges are rated using a standard set of vehicles to have a reliable and constant summary of the load carrying capacities and it is called Legal Loads. So, the load rating is performed to ensure the safety of general public and traffic using highway bridge structures. Bridges that have inadequate load capacity are considered and posted for restricted loads.

For conducting routine load rating of highway bridges, authorities can perform load rating based on the AASHTO LRFR (Load & Resistance Factor Rating). Routine Load Rating can be defined as vehicular live load capacity of a bridge by using as-built bridge plans or latest field inspection (NBIS). And, it is expressed as a Rating Factor (RF) or in tonnage for a particular vehicle as mentioned above.

Benefits of LRFR are uniform reliability in bridge analysis, more uniform posting levels, guidance for evaluation of overloads, procedures to ensure more consistency and uniformity in rating, optimal load factors for lower volume roads, introduction state-of-the-art technologies that could benefit existing bridges, and evaluation of bridge serviceability or service limit.

LRFR also results in bridge safety certification, provides data to support bridge rehabilitation or replacement needs and prioritization, and generates data that must be submitted to the National Bridge Inventory in order to comply with NBI Standards.

Thus, having routine, accurate and up to date Load Ratings are important to meet inspection and reporting requirements and ensuring that the correct bridge postings are achieved. They also allow infrastructure owners to make informed asset management decisions with regard to overall traffic pattern management, asset rehabilitation/ reinforcement to meet current or changing demands over time, and ensure that bridges can be safely operated and utilized.

Routine Load Rating can occur at several stages throughout a bridge’s useful life; during design phase, during primary inventory inspection, and/ or during the routine NBIS (National Bridge Inspections Standards Regulation) safety inspection of a bridge in the operation stage.

Routine/ Contract Load Rating can also be conducted when changes in the live or dead loads on the structure occur, and/ or when there is any physical change in structural members of the bridge (e.g. after retrofitting, maintenance operations or rehabilitation/ reinforcement activities). Routine Load Rating can also be helpful to ensure the safety of the bridge, particularly since natural events (such as a flood, earthquake or hurricane) or new construction activities in the area of bridge structure may cause damage or changes to the bridge or cause geophysical changes to the area of the bridge.

Authorities and other bridge structure owners spend significant resources in validating and refining their load rating models and ensuring compliance with rule changes that could require re-rating of bridges based on updated requirements. Monitoring instruments are widely used during the load rating process.

The applicable, measurable and monitorable quantity in bridge routine load rating is strain.

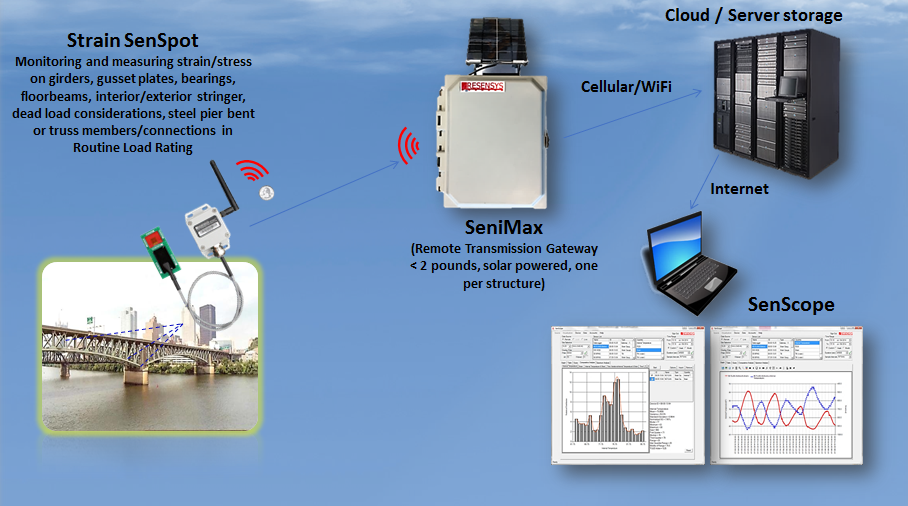

The Resensys Wireless Strain sensors are well-suited for bridge structure routine load rating due to their quick and easy installation, accurate, reliable, repeatable results, and the fact that there is no need for calibration in the field.

So, Resensys’ wireless design reduces installation cost and time, making it a cost-effective way for owners to get the data they need. The ultra-low power usage allows multiple instances of short-term use (bridge routine load rating), which is ideal for load rating in the field. It also provides flexibility if authorities wish to keep the sensors on their structures permanently for long-term use (bridge structure health monitoring).

Resensys SenSpot sensors are able to monitor structural quantities in concrete, steel and composite materials under wet, humid and extreme weather conditions. The product is corrosion resistant and can withstand salty environments.

More Details

More Details