Home > Applications > Tunnel Monitoring

Underground structures such as tunnels are very important in transportation. Tunnels can be used for carrying freights and passengers (commuter tunnels), water (hydro-electric and hydraulic applications), sewage, etc. Tunnels are more cost-effective than open cuts beyond certain depths. Tunnels avoid disturbing or interfering with surface life and traffic during construction. A tunnel boring machine (TBM) is a machine that is used to excavate tunnels and it can bore through different kind of ground conditions, hard rock, sand, etc.

One of the critical aspects in tunnel design and construction is the monitoring of tunnels, surrounding environment and building structures within the affected/predicted region of tunneling construction. This monitoring occurs during the construction, commissioning and also during the lifecycle/ maintenance phases of the tunnel. So, monitoring and measuring different structural quantities in tunneling must be part of tunnel design, planning and execution and can have significant impact on the costs/ profitability of the tunneling venture and also on the safety and risk of property damage during the venture. Different tools are used to support with these measurement observations, and indicate the need for adjustments to the tunneling plan or the need for preventative repairs. Instrumentation and monitoring is a necessary component of site investigation, design confirmation and safety of the tunnel structures.

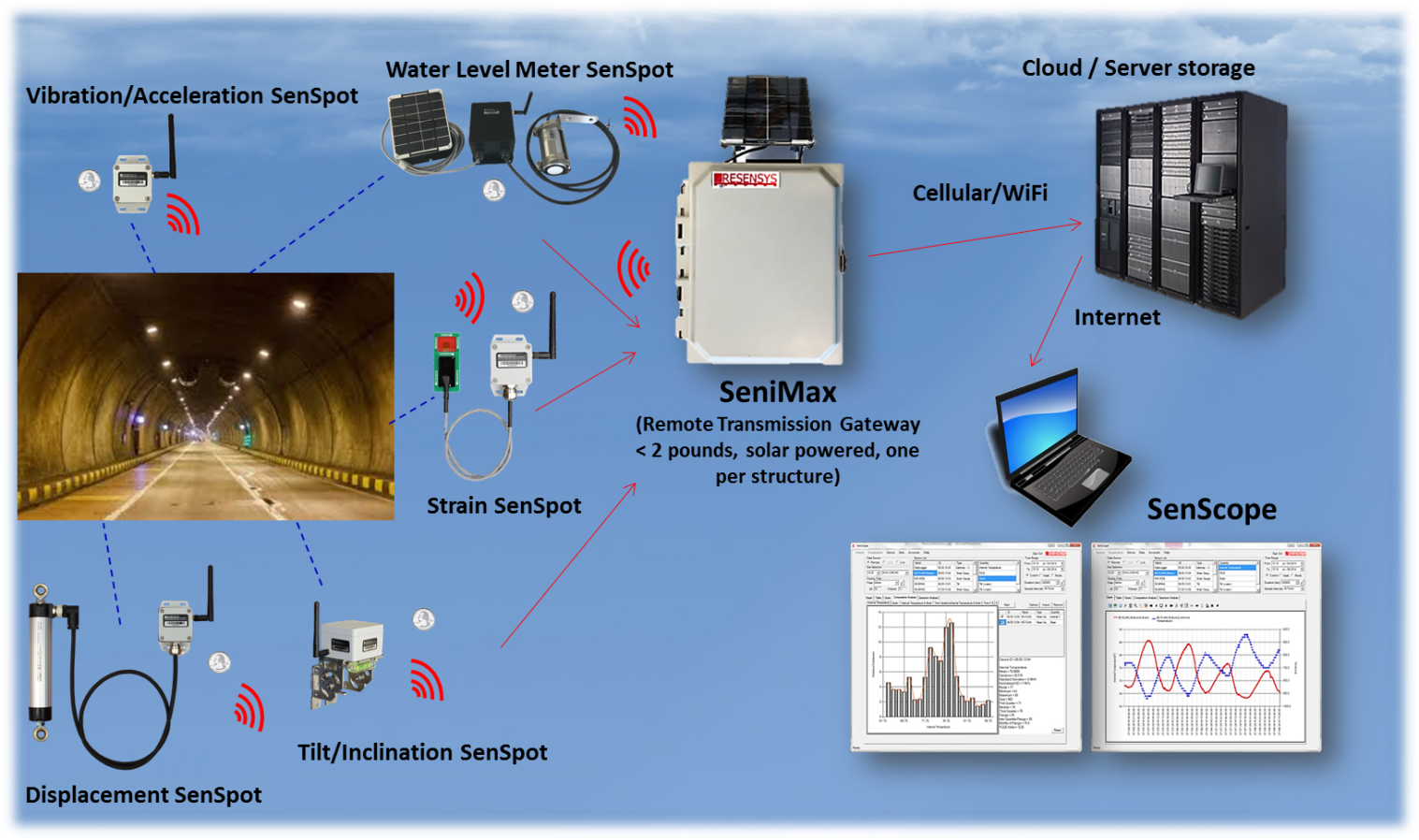

Resensys Wireless condition monitoring sensors can be implemented during each of the three phases of construction of tunnels and subways; before operation, during operation and after operation for examination. The applicable, measurable and monitorable quantities in monitoring of tunnels, surrounding environment and building structures within the affected/predicted region of tunneling construction are strain, tilt/inclination, displacement, vibration, underground water level and ambient temperature.

Strain (Tunnel Lining)

Pre-cast Tunnel Liners (Tunnel Lining) are prepared to match the requirements of a tunnel. They are planned and designed to resist the earth pressure and groundwater head. Also, they deliver the basis for the tunnel’s ultimate use. Multiple liner segments are combined to make a ring.

Wireless Strain Gauge SenSpot can be used for monitoring strains in Commuter Tunnel Linings and concrete pre-cast segments. They can also be applied, to measure and investigate tension in rock bolts and anchors used in tunneling projects, by monitoring strain variations and monitoring loads on struts.

The significant goal of stress/strain measurements during construction in mountain tunnels is to ensure that ground pressures are sufficiently measured and controlled, i.e., there exists an sufficient margin of safety against collapse, including roof collapse, bottom lift, failure of the excavation face, yielding of the support system, etc. Strain/Stress measurements devices are typically mounted in the roof of tunnels and at certain points along walls of the tunnels to measure and monitor stress/strain components in tunnel projects.

Tilt/Inclination (Tunnel Lining and Surrounding Structures)

Resensys Health Monitoring System can be used for Tunnel Concrete Segments and can be installed in tight spaces and hard-to-access places around the TBM without the need for additional wiring. The system includes a series of Wireless Tilt/Inclination SenSpot, fixed to the tunnel wall on each of the pre-cast concrete segments created in place as tunnel lining by a Tunnel Boring Machine (TBM). It is supposed that each concrete segment is a rigid body and the complete ring deforms by rotation of the single segments that relates to another one. The rotation points are the connection sides between adjacent segments. This hypothesis is very often considered as acceptable by tunnel designers and authorities. While this is close to reality, points should be investigated using traditional convergence measurements or surveying methods to confirm its rationality for each separate tunneling circumstance.

Displacement(Surrounding Structures)

Wireless Displacement/Crack Meter SenSpot sensors can also be used to measure movement and opening of existing cracks in nearby building structures in the tunneling projects area. This can be important when tunnels are being constructed in historic or previously developed areas, or where ongoing tunnel operations could be considered to have a potential effect on vulnerable buildings.

Vibration (Surrounding Structures)

Vibration monitoring can be important during the tunnel construction and operation stages (in applications such as commuter tunnels) to monitor vibrations associated with the tunneling activity. It can also be important to understand whether subsequent vibration effects due to separate construction actions conducted on the surface are causing vibrations that might have a harmful effect on existing tunnel or subways within proximity of the new project location. In each of these cases (new tunnel excavation and separate but concurrent construction activities), ground vibration occurs. These vibrations can damage buildings structures and roads within the tunneling zone and cause delays and excessive costs to the projects. Resensys monitoring system are able to measure vibration levels using Wireless Vibration/Acceleration SenSpot sensors. Measured data is viewable very quickly by Resensys software; SenScope™ and depending on the projects, alarm systems or triggers can be set using pre-determined thresholds. Thus, stakeholders are able to take informed actions in a timely manner. Resensys monitoring systems can thus warn the project authorities by emails to pre-determined decision-makers and the alerts can be seen through details on SenScope™ and authorities’ PC/Laptop.

Water Level

To monitor underground water level within the affected/predicted region of tunneling construction, Wireless Ultrasonic Level Meter SenSpot™ can be used. This device provides an easy way to install a scalable solution for measuring water level or any kind of distance (e.g. height, object detection and dimensions).

General Characteristics of Resensys Systems

Resensys Wireless SenSpot sensors are well-suited for tunneling applications because of their accurate data collection and high rates of data transmission. They are wireless, and low-power, meaning that they are easy and cost effective to install and maintain. They have adjustable triggering threshold and sampling intervals and provide accurate, reliable and repeatable results, without need for calibration in the field.

SenSpot™ data helps the stakeholders and engineers make informed decisions about how quickly construction can progress. In addition, Resensys products can provide early warning of imminent failure and catastrophe by their Alarm feature by alerting when pre-set data thresholds have been exceeded. Resensys real time monitoring system can thus pre-warn of potential effects on adjacent structures and utilities.

Resensys sensors’ ultra-low power usage allows for both short and long term use. A key benefit of this power-efficiency is that short-term uses can be easily repeated multiple times without the need for battery replacement or intra-test charging if users wish to use the products for their own experimental tests. After tests, the same sensors can also be left on the tunnel or structures for long-term use (tunnel/structure health monitoring). After installation, SenSpot™ does not need battery replacement or any other maintenance during its entire service life.