Home > Application Notes > Bridge Load Rating

The Load Rating is a measure of bridge live load capacity. Load Rating is commonly defined in two forms:

• Inventory Rating, as defined by the current AASHTO Manual for Bridge Evaluation, is that load, including loads in multiple lanes that can safely utilize the bridge for an indefinite period of time.

• Operating Rating, defined by the same manual, is the maximum permissible live load that can be placed on the bridge. This load rating also includes the same load in multiple lanes. Allowing unlimited usage at the Operating Rating level will reduce the life of the bridge.

Having accurate and up to date Inventory and Operating Ratings are important to meet inspection and reporting requirements and ensuring that the correct bridge postings are achieved. They also allow infrastructure owners to make informed asset management decisions with regard to overall traffic pattern management, asset rehabilitation/ reinforcement to meet current or changing demands over time, and ensure that bridges can be safely operated and utilized.

DOTs, Authorities and other asset owners spend significant resources in validating and refining their load rating models and ensuring compliance with rule changes that could require re-rating of bridges based on updated truck requirements.

The applicable, measurable and monitorable quantity in bridge load rating is strain.

The Resensys Wireless Strain SenSpot sensors measurements responses are well-suited for bridge structure load rating due to their quick installation, and accurate, reliable, repeatable results, with no need for field calibration. The monitoring system can be installed during the routine NBIS (National Bridge Inspections Standards Regulation) safety inspection of a bridge. Resensys’ wireless design reduces installation cost and time, making it a cost-effective way for owners to get the data they need. The ultra-low power usage allows short -term (bridge load rating) and long-term use (bridge structure health monitoring).

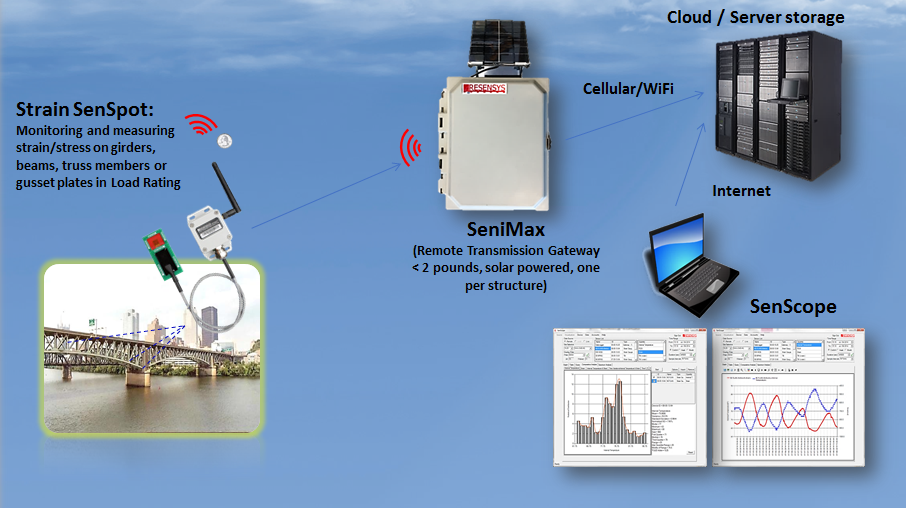

Resensys SenSpot sensors are able to monitor these structural quantities in concrete, steel and composite materials under wet, humid and extreme weather conditions. The product is corrosion resistant and can withstand salty environments.A Resensys Bridge Load Rating solution comprises Wireless Strain SenSpot sensors on the location of girders, gusset plates, bearings and truss members, a SeniMax Gateway to transmit data away from the site and the SenScope display user-interface.

Resensys SenSpot sensors are easily placed/ installed on critical elements as determined by inspection, finite element modeling, load rating model or authority’s/client’s suggestion. Since they are wireless, no additional wiring is required, and the sensors are mounted with adhesive or flange mounted depending on the application. A Senimax data acquisition unit is conveniently mounted nearby or conveniently mounted within 1.0Km (0.62miles) free space of the SenSpot Sensors and a SenScope Module is installed on the client’s/authority’s laptop or PC.

A complete Resensys SHM system includes software and hardware components for (1) the reliable collection of SenSpotTM data, (2) aggregation of the data, (3) the addition of timestamps, (4) communication of encrypted data to a remote server, and finally, (5) an interface for data visualization and detection of structural issues. Figure below shows a picture of a practical Resensys SHM system, which can be used for structural monitoring.

The system includes the following components:

• SenSpot sensors (for strain): which are attached to a bridge (Required number of sensors per structure, depending on design and monitoring needs).

• SeniMax: which collects SenSpotTM data at the site and sends it to a remote server (one unit can cover as many as 100 SenSpotTM sensors).

• Repeater: may be used to extend the range of the SenSpotTM sensors.

• SenScope: software for data analysis and visualization

More Details

More Details