Home > Applications > Bridge Monitoring

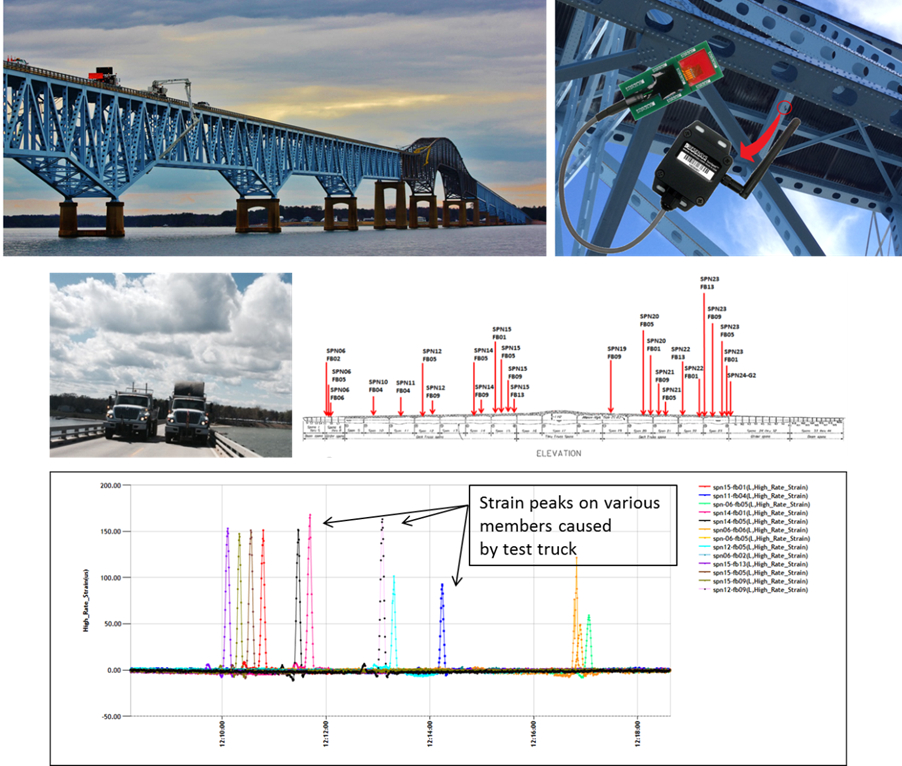

For many people in the United States, driving over one or more of the nation’s 602,000 highway bridges is part of their daily commute, and recent statistics from the Federal Highway Administration indicate that more than 145,500 of these bridges are either structurally deficient or functionally obsolete. Assessing the structural stability of fracture critical or scour critical bridges, conducting load rating activities and making informed asset management decisions is very important because it allows structural issues to be pinpointed and necessary maintenance and repairs to be planned. This ensures bridge safety and longevity. Resensys has developed its wireless structural health monitoring solution for existing bridges and bridges under construction that features small, low-cost, easy-to-install wireless sensors that measure a variety of variables affecting the performance of a bridge. Bridge bearing/ expansion joint monitoring, scour critical monitoring, fracture critical monitoring, and displacement and strain monitoring are just a few of the ways that our products help our customers to make informed decisions and develop data-driven solutions. Our Application Notes and Sample Projects provide additional insights into how our products are meeting our customer’s monitoring needs.

Data collected from the sensors can provide bridge owners with diverse information on bridge structural health such as overstrain, changes in load conditions, deformation, excessive vibration, crack development and growth, and conditions that are conducive to corrosion. Resensys monitoring system is unique in that it is extremely low power. For example, an individual sensor needs only 4 μW to operate.

Resensys' SenSpot™ sensors are also capable of monitoring specific variables that indicate favorable conditions for corrosion of reinforcing steel in concrete, moisture, electrochemical activity, and chloride concentration. These sensors possess a small probe that is inserted into the concrete at a depth that enables close proximity to the reinforcing steel. The type of probe used on the sensor corresponds with the conditions being monitored in the concrete (i.e., the amount of moisture, the concentration of chloride ions, or the presence of an electrochemical current between the steel and the concrete).